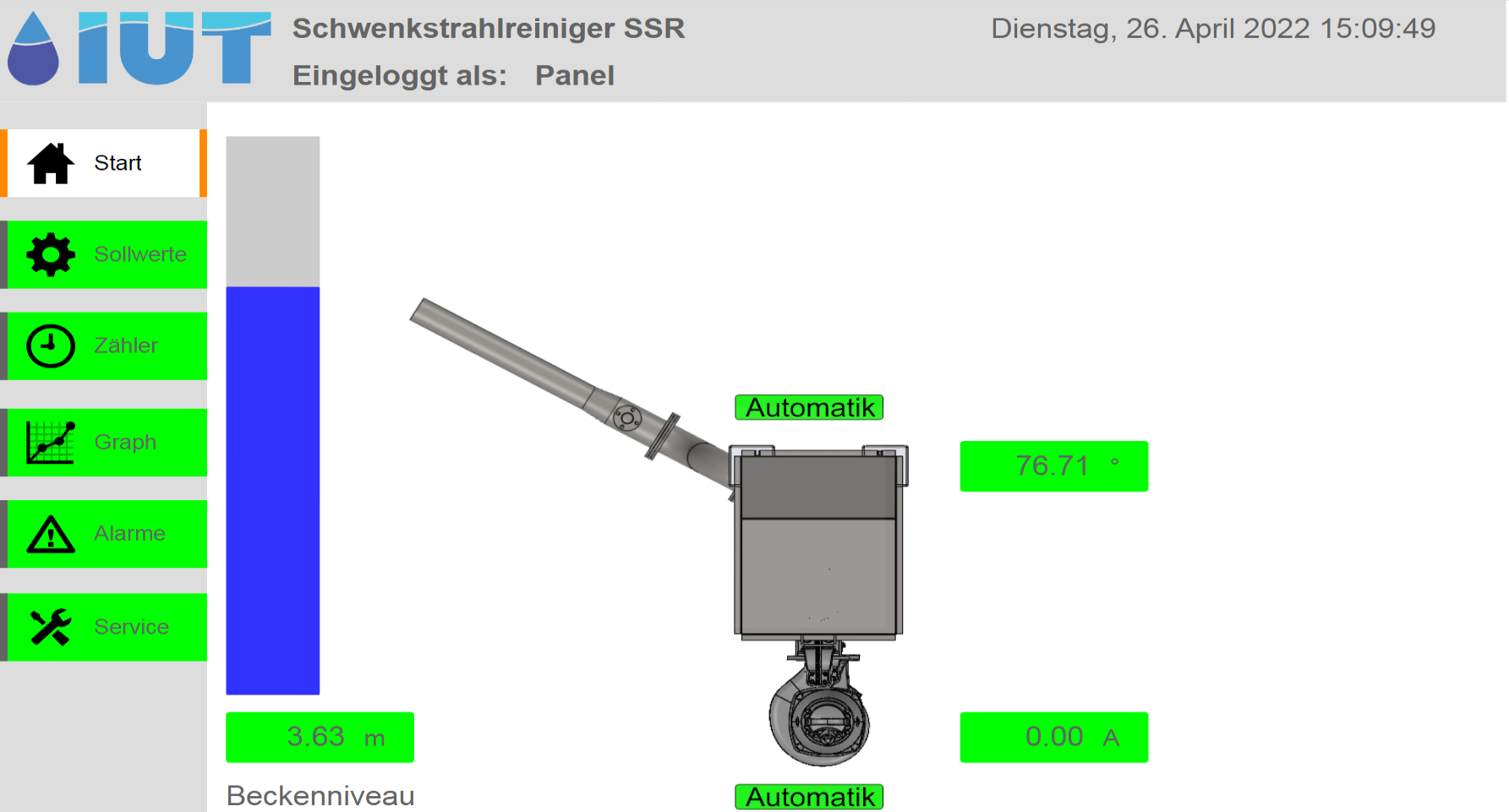

Swivel Jet Cleaner SSR

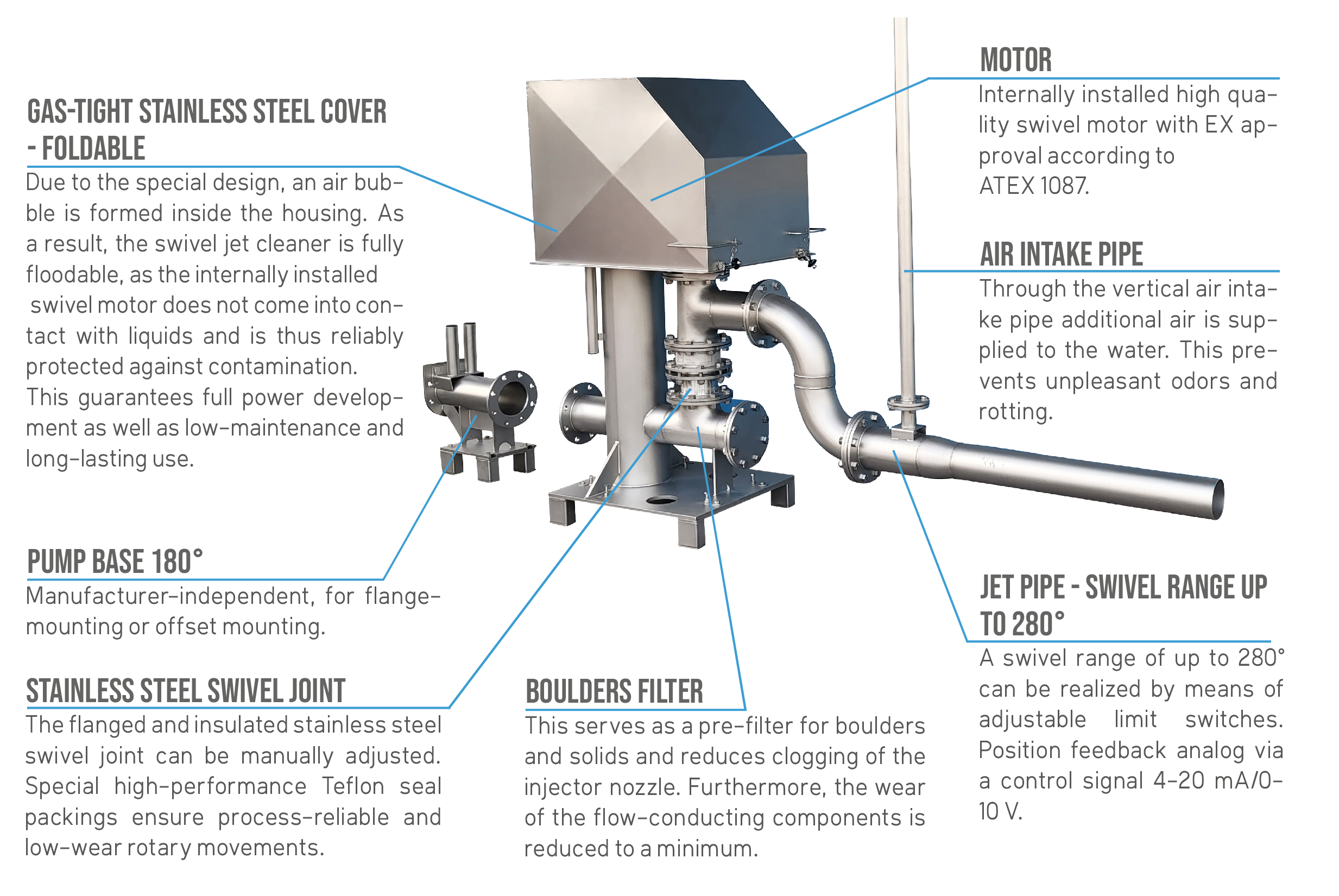

Fully submersible swivel jet cleaner with boulders filter and hinged, gas-tight stainless steel cover

Automatic cleaning and flow generation in stormwater basins to ensure the long-term operation of the plant.

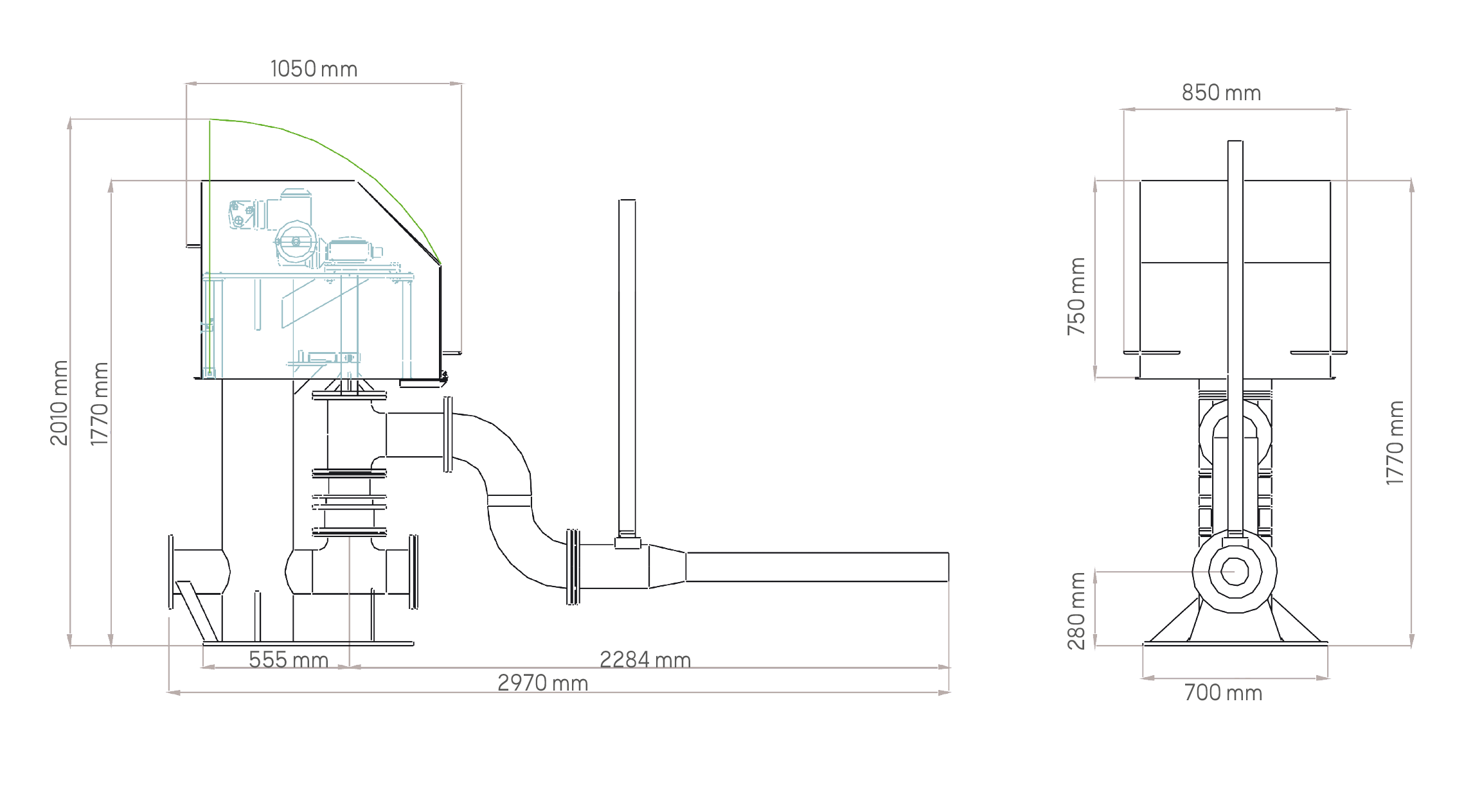

Size

DN 150

(DN 200) *

Material

Stainless steel A2-1.4301

(A4-1.4571) *

Swivel Range

Stepless up to 280°

(adjustable limit switches)

Pump

Manufacturer-independent, flange-mounted

or offset mounted

Circulation

Up to 300 cbm/h

Rated power

4,9 – 22 kW

*(on request)

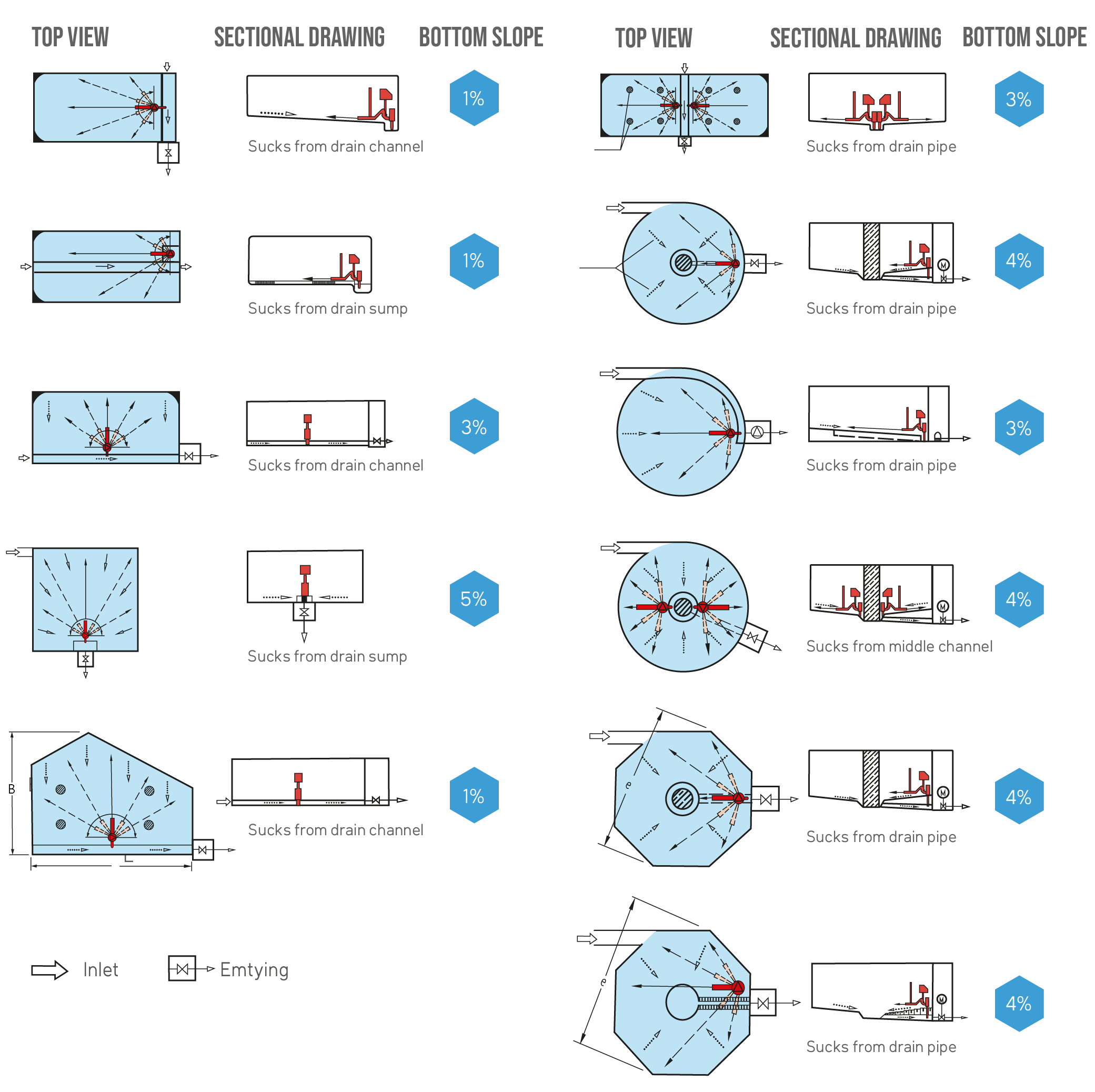

Functional principle

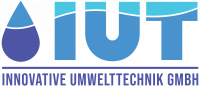

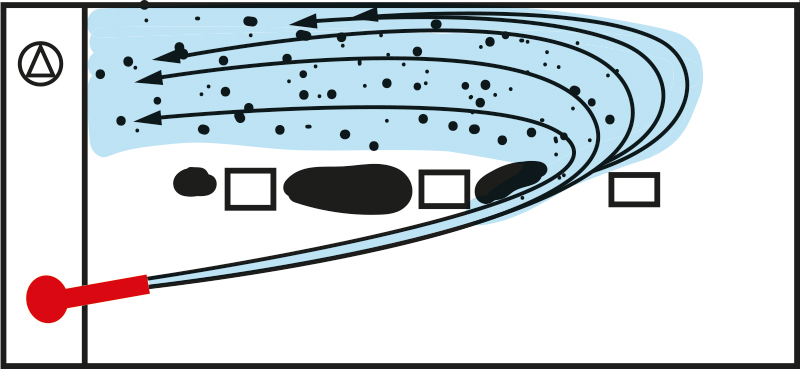

The swivel jet cleaners work on the principle of the water jet pump. A pump delivers a volume flow into the jet pipe. The air is added to the water in the area of the air intake pipe and is emitted horizontally from the jet pipe at high speed.

This creates a flow which keeps the particles contained in the medium and prevents them from settling on the bottom. The suspended solids are reliably flushed out of the basin during the emptying phase.

Due to the supplied air, the swivel jet cleaners also have an aeration function. This prevents unpleasant odors and the formation of rot.

Working Method

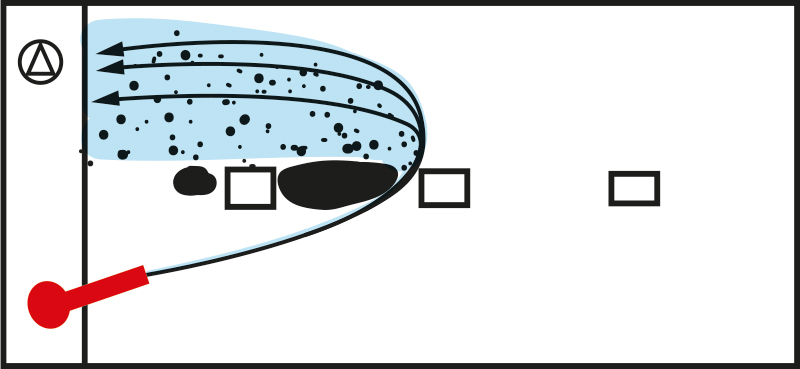

During the accumulation phase of the basin, the swivel jet cleaners are in the standby mode. When the basin has filled up the cleaners start the aeration. The basin is aerated by means of an intermittent jet with the jet pipe pointing rigidly in one direction. The actual cleaning process starts in the emptying phase of the rain basin. The jet pipe swivels during this stage and stops at defined stopping points for a certain period of time (interval jet). The contents of the basin are thoroughly mixed in this process.

Final cleaning begins at a residual water level (e.g. 1 m). The bottom of the basin, the walls of the basin and any pillars are cleaned by the concentrated cleaning jet. Suspended solids are removed from the basin during the emptying phase.