Swimming stairs BZS

Stainless steel self floating stairs with railing on both sides

Safe and hygienic entry into watered special buildings

Suitable for installation in stormwater retention basins and pumping stations of explosion class I and II

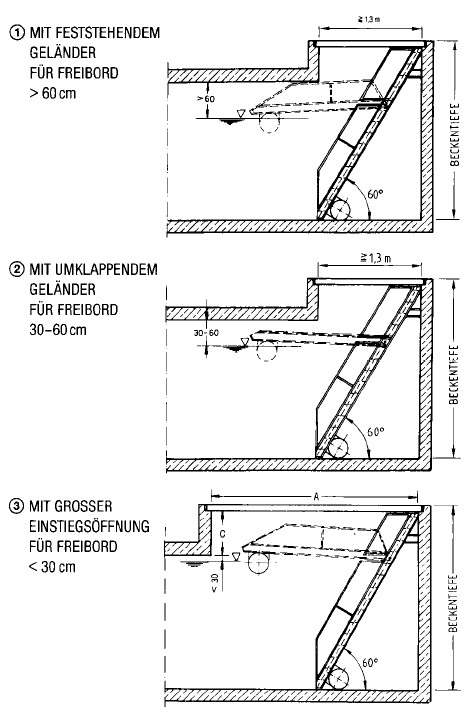

Basin depth and building conditions

The standard stairs are designed for basin depths up to 5 m. Depths of up to 7 m can also be bridged using a special construction with counterweight (or an intermediate platform). Standard ceiling thickness is 300 mm. Special designs for ceiling thicknesses up to 550 mm are possible. A freeboard of 750 mm allows stairs with fixed railings. A freeboard up to at least 550 mm allows foldable railings. If the freeboard is lower, the basin must be edged and earth backfilled In the case of the hinged-cover staircase, the frame (provided in advance) must be inserted into the slab formwork and cast in with it. In the case of the swimming staircase, the fastening is done subsequently by dowelling. Swimming stairs operate at an angle of approximately 60°.